In the modern days where the world has shrunk to the size of a palm, information has been digitized to fit the screen.

While the technologies that come together to make mobile devices have become more capable, the source of their power doesn't progress as fast. As a result, consumers end with capable devices but with a very limited usage between charges.

Not many mobile phones can operate a full day of normal usage without having to scream for a recharge.

Manufacturers know this very well. And this is why they are all trying to develop more advanced technologies to make devices last longer between charges.

This includes: making smaller and smaller system-on-a-chip (SoC) so the chips require less electricity, larger batteries by squeezing every micrometer of available space, and so forth.

Another way, is by introducing more capable displays but that are also more power efficient.

One of which, is by using LTPO.

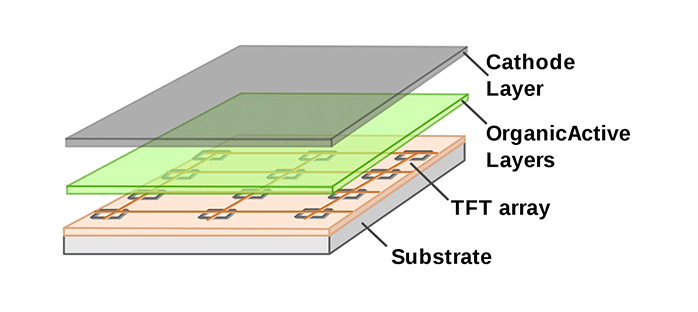

Traditionally, the construction of OLED displays rely a bunch of layers.

The most crucial layers are the organic light-emitting diodes (the OLED itself), which is the layer of organic material that emits light through a pixels that are etched into the glass above it; the layer that can be stimulated with electrical current; and the layer that consists of an array of thin film transistors (TFTs) located below them.

Together, they create what it is called the "backplane."

On OLED displays, the TFTs are traditionally made from Low-Temperature Polycrystalline Silicon (LTPS).

And here, LTPO or "Low-Temperature Polycrystalline Oxide", is a display backplane technology that combines both LTPS TFTs with Oxide TFTs (IGZO, Indium Gallium Zinc Oxide).

LTPO uses the somewhat standard LTPS materials for the “switching” circuits to turn its pixels on and off during a frame, and at the same time, uses IGZO for the “driving” circuits that keep the pixels powered with a certain voltage during that same frame, by determining how bright the pixels should be, and what color combination they should be.

In other words, LTPO is a hybrid display.

The star in LTPO, is that IGZO, the semiconducting material that makes the display a different one.

The material IGZO was first developed by Hideo Hosono's group at Tokyo Institute of Technology and Japan Science and Technology Agency (JST) in 2003. He discovered that IGZO is a kind of TAOS (transparent amorphous oxide semiconductor), and can be easily coated onto plastic film using low temperature vacuum sputtering.

It was also JST that patented the technology, before licensing it to Samsung, Sharp and LG for their TVs, as well as to other brands.

IGZO is an abbreviation for indium (In), gallium (Ga), zinc (Zn) and oxygen (O). It's a compound of those elements that make the backplane part of the display. TFTs made from IGZO have increased electron mobility on their amorphous silicon, which improves speed and resolution.

IGZO has this advantage thanks to its ability to be deposited as a uniform amorphous phase while retaining the high carrier mobility common to oxide semiconductors.

When it was first introduced and commercialized, IGZO-powered displays were expensive to make and also to scale.

But because the technology within is superior to that of LED displays, IGZO-powered displays like the LTPO offer a way forward. The technology boasts substantially greater electron mobility, which in turn makes them easier to scale downwards into smaller sizes without a loss in performance.

The technology behind LTPO has the ability to save around 5-15% of energy if compared to the LTPS backplanes.

Besides that, LTPO which boasts thinner TFTs, capable of reduce refresh rates of devices to near zero when not displaying active information on the screen.

This is why Apple Watch with its Always On feature doesn't consume much energy.

Because it's more expensive to make and with the said advantages, the display that is applicable for both OLED and LCD, is initially targeting the higher end of the scale. What this means, the technology is initially aimed for higher-end phones with OLED displays

The main drawback of LTPO is that the IGZO TFTs are larger and so the display density may be compromised. And also because LTPO uses TFT for each pixel, the IGZO transistors could also compromise the sharpness of the screen.

Further reading: The '40-80 Rule' Battery Charging: Dealing With Lithium-Based Chemical Problems